Heat exchangers are devices extraordinarily made for successfully moving the heat from a liquid to another liquid over a hard surface. This heat move can be osmosis or heat dispersal. Heat and cooling exchangers are noticed every day on a large number of contraptions, from boilers, or heaters, to refrigerators and cooling structures. As a contraption for heat move, it is an inspiration driving the heat exchanger to send heat as successfully as could truly be anticipated. This allows the decision of a conclusive contraption, for example, when it makes an appearance to saving energy by recuperating wasted heat and it is significant to make it. By virtue of a maltreatment of energy or heat change that is not recovered, a brazed plate heat exchanger redirects the mysterious movement of heat into something that can be used. This dependence reflects significantly in the financial outlines of the best suppliers of heating plate exchangers, since the constrained air system industry has extended at a fast.

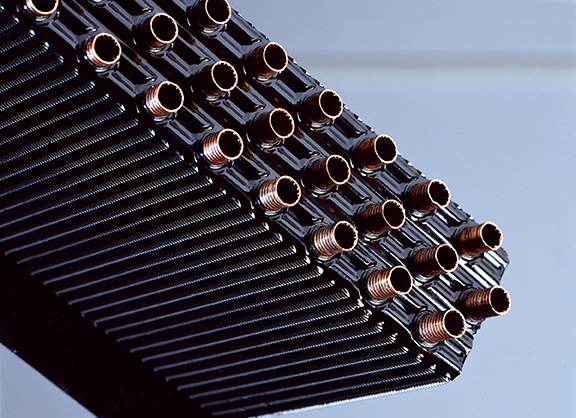

Whether or not for heating, ventilation, cooling, the brazed plate heat exchangers are flawlessly suitable for all applications. In ventilation, endlessly cooling systems, brazed plate heat exchangers ensure clean air and a virus breeze. The brazed plate heat and cooling exchangers are a piece of equipment preferred for the mechanical business. The heat brazed plate exchangers, close by the air to water heating and cooling exchangers are the central pieces of any cooling structure. Without them, this machine would be only a fan. Associations that creation environment control systems are absolutely dependent after heating exchanger creators. The microchannel heat exchanger is comprehensively used for heating, cooling and even refrigeration. Significant Ventures that usage strategy are the power plants, compound and petrochemical, petroleum and refined oil, oil gas dealing with plants and waste water treatment.

Gaskets that interface the circles are the essential weakness of this heat plate exchanger’s packaging. Dependent upon the speed of the fluid and disintegration, seals can begin to lose, after a period, after the individual time that require upkeep and replacement. Pressure drop in the heat and cooling exchanger is high, and this could require the purchase and working costs and more capable siphoning structure. Though the help is more straightforward for a plate exchanger, it can regardless become plugged up. This prompts broad stretches of inactivity. To guarantee that your contraption is properly managed, you ought to clean it reliably. Review that all that stores can be moved by manufactured implies. This cleaning should simply be done by a specialist, in light of the fact that the less than ideal use of engineered mixtures can hurt the device. Moreover, mechanical removal uses different techniques. There are novel dismissing brushes that show up at the most diminutive corners of the device. Despite how you choose to clean your heat exchanger, recollect that mentioning an expert’s assistance is recommended. Endeavor and prevent fouling whatever amount could be anticipated.